Home ► Company

Westfälische Drahtindustrie GmbH

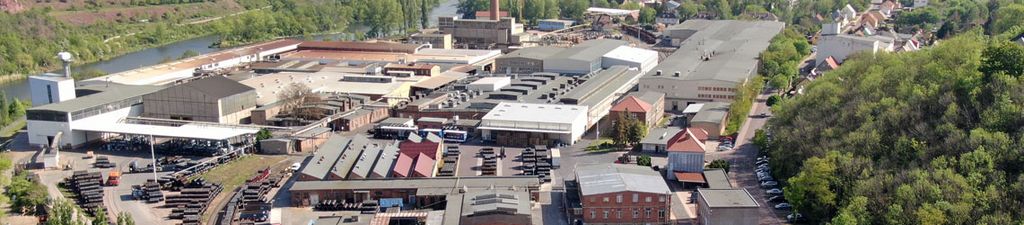

Westfälische Drahtindustrie GmbH, based in Hamm, is the largest independent wire producer in Europe.

For over 160 years now, WDI has been manufacturing wire and finished products at 15 locations in Germany with around 1,300 employees in the following business areas:

High quality wire | Bright steel | Construction steel | High performance wire ropes | Prestressing steel | Welding technology | Overhead power lines | Fence meshes

Our products are found in around 150,000 applications and uses worldwide.

The enormous variety of wire products manufactured fulfils customer requirements. The range of uses for high quality wires is so extensive that only a few examples are given here.

The most important sales markets for WDI wire products are wire and bright steel for mechanical engineering, wire for the construction industry, wire and bright steel for the automotive sector and wire strands for overhead power lines in the energy industry.

Image film

In today's highly specialised world, wire products are an essential part of technical progress. They are of fundamental importance in times of global networking and global trade.

Breathtaking architecture, gigantic machines, a reliable power supply, the automotive and aerospace industries, connecting welding technology, fossil energy production and the research and development of new chemicals and medical products would be neither feasible nor functional without the use of wire.

Special wire products are used in the furniture and fittings industry, for the production of spring steel wire and upholstery spring wire for mattresses and seating furniture, by sports equipment manufacturers and in the household goods industry.

This shows that the range of applications for wire is almost inexhaustible and will continue to link the technical progress of our world in the future.

Accident management information

Information for the public in accordance with § 8a of the 12th BImSchV

Since June 2022, the premises of Westfälische Drahtindustrie GmbH (WDI) on Otto-Brenner-Straße in Hamm have been classified as a lower class operating area and is therefore subject to the basic obligations of the Hazardous Incident Ordinance.

Corporate philosophy and quality policy

Corporate philosophy and quality policy of Westfälische Drahtindustrie GmbH

The development of Westfälische Drahtindustrie GmbH is an expression of a corporate policy that is directly related to the endeavour to achieve product quality and complete fulfilment of customer requirements. Customer expectations are honoured where appropriate for the company.

Customer satisfaction is a key component of our corporate philosophy.

The company management has an obligation to maintain and strengthen this reputation and defines its quality policy with the quality management system. The manufacture, distribution and trade of products of optimum quality is our top priority, which can only be maintained through the quality awareness of all employees and by promoting awareness. This results in the obligation and the right to prevent any circumstances that jeopardise the quality of our products.

The company management uses the quality management system to define its quality policy; it provides an appropriate description of the quality assurance system. Its application ensures that the legal, organisational, commercial and technical activities that have an impact on the quality of execution are planned, controlled and monitored, and that the contractually agreed QM measures are adhered to.

In order to achieve our quality and business objectives, we are constantly endeavouring to bring about improvements. In addition, site-specific quality objectives are derived from the quality policy at regular intervals and are monitored and evaluated accordingly.

The quality management system fulfils the requirements of ISO 9001 and the provisions of contractually applicable national rules and regulations.

The regulations of the quality management system in accordance with IATF 16949 and the provisions of contractually applicable national and international rules and regulations apply to the sites PC 3 Eisen and Kaltstauchdraht (iron and cold heading wire) in Hamm and the PC 10 Iserlohn-Kalthof site.

Through this declaration, the management requires all persons employed to carry out their work in accordance with the descriptions of the quality management system in order to ensure that the quality of all company products meets the requirements.

Planning

Quality targets are set, monitored and evaluated by the management in consultation with the site-specific PC management with the involvement of quality management and the production areas or production sites.

January 2020 | Westfälische Drahtindustrie GmbH

Three letters symbolising wire

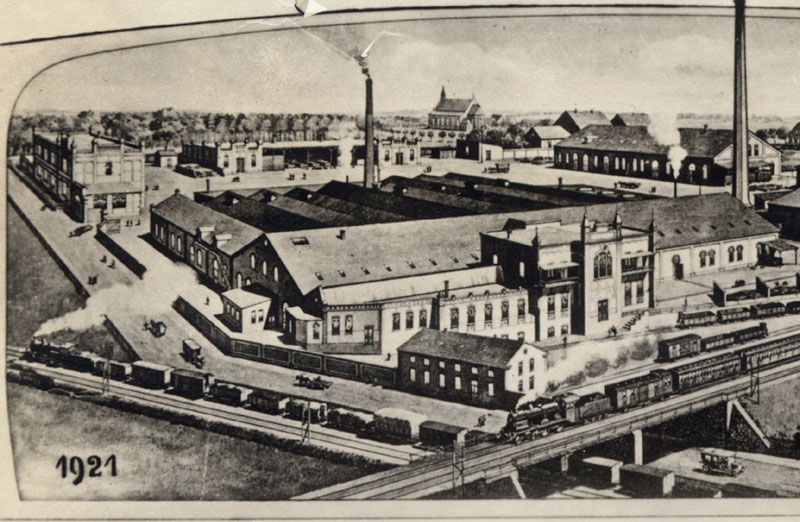

Westfälische Drahtindustrie was founded in 1856 and was listed as a public limited company in 1872, without the obligation to include the suffix "AG" in the company name; a privilege that has remained permanent. With only a brief interruption, the company name "WDI" was the symbol in letters for the wire production site in Hamm, Westphalia – for a period of over 160 years.

1797

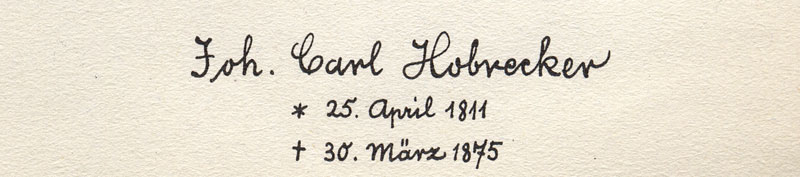

During the early days of the wire industry in Hamm, the brothers Wilhelm and Johann-Caspar Hobrecker (sons of a Sauerland ironmaking family) took over their father's business – a forge located at the north gate of Hamm They manufacture bicycle spokes and agricultural chains, among other things

The name Hobrecker became an integral part of the development of the wire industry in Hamm. The family history can be traced back to 1313 - the name was formed from "Hobräck" - a lonely farm on the "Brachfeld auf der Höhe" (in Dahl near Altena).

1820

The "Concession for the establishment of an iron rolling mill on the site and on the slope of the former sawmill at the Nordenthor in Hamm", granted by the Royal Prussian Government in Arnsberg, now enables the industrial production of drawn wires for further processing, e.g. into binding wires and nails, using the water power of the Lippe; there is also a rolling mill for the production of sheet metal, which results in the manufacture of furnace tubes and boilers, among other things.

The company name was initially "Gebrüder Hobrecker", later changed to "Wilhelm Hobrecker". Connections with the Krupp company were already established at this time (due to the supply of primary material), as can be seen from an exchange of letters from 1821/22 "to Mr Krop in Essen" (a little later also to Mr Kroup).

Friedrich Krupp was visiting his cousin D. Schmitz in Hamm and had also visited the Hobrecker Bros. factories and said that he could be asked for advice at any time.

Carl Hobrecker, a son of the founder Wilhelm Hobrecker, was familiar with the technical innovations from travelling in England.

He recognises the need for industrialisation, separates from the parent company in 1854 and joins forces with the factory owners Hermann and Julius Witte and Hermann Herbers from Iserlohn.

This is where the real story of the Westphalian wire industry begins.

1856

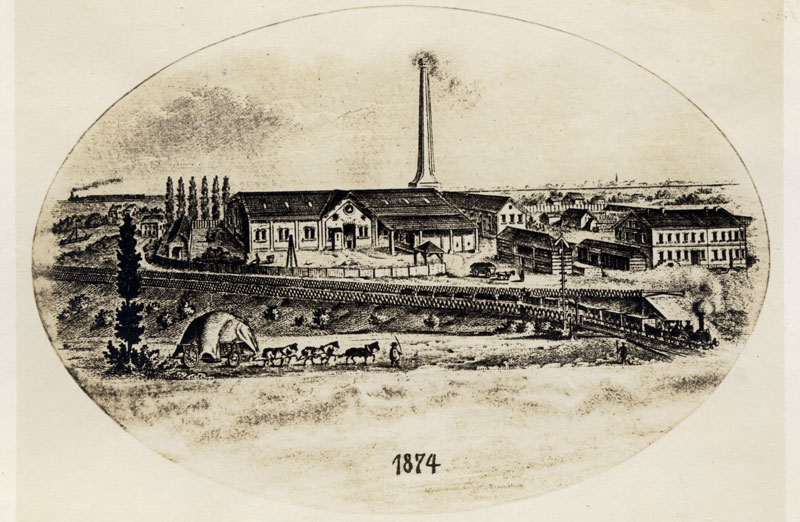

In this year, another wire factory is founded: Hobrecker, Witte & Herbers

It is located on a huge site (60,000 square metres) near the railway line connecting Cologne and Minden and the important road connection to Unna and Dortmund. Steam power is now used here (for the first time in Europe in a wire mill) to produce wire rod and drawn wire.

1865

From 1865, the main factory was named "Eduard Hobrecker" after the owner at the time, Eduard Hobrecker (1842 - 1872). His brother Otto becomes his successor and relocates the company further north to the site of the so-called "Hammer Hütte". He replaced the water power of the Lippe with steam engines and the plant was connected to the railway.

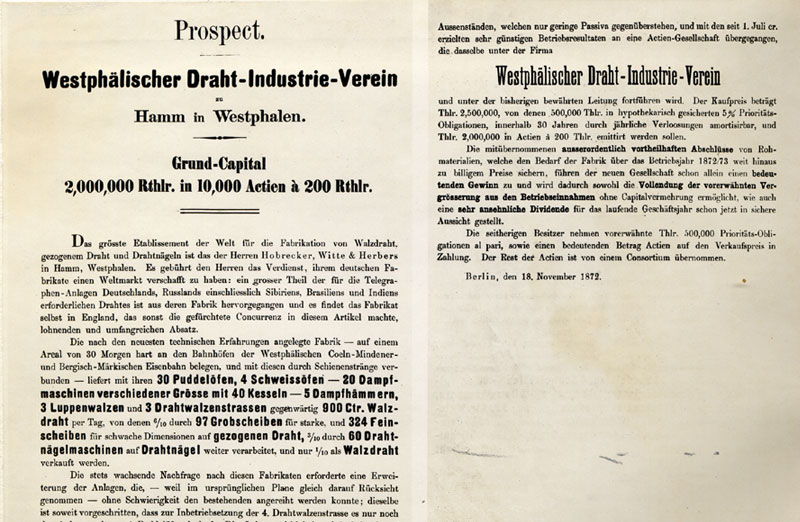

1872

At a general meeting in the hall of the "Gasthof zum Grafen von der Mark", it is decided to rename the wireworks "Aktiengesellschaft Westphälischer Draht-Industrie-Verein", and the entry in the commercial register is made on 15 December. The new public limited company takes over the factory facilities, machines and staff of the company "Hobrecker, Witte & Herbers". It becomes "...the largest establishment in the world for the manufacture of wire rod, drawn wire and wire nails..." as the Berliner Handels-Gesellschaft reported in the Kölnische Zeitung newspaper. Carl Hobrecker's sons, Hermann and Stephan, are the first directors of the new public limited company.

Many eventful years later...

1972

A change in ownership gives rise to Vereinigte Drahtindustrie GmbH (initially VDI, from 1974 VDG). The merger of WDI with Klöckner-Drahtindustrie (KDI), Düsseldorf - with plants in Düsseldorf, Ründeroth, Kehl and Göppingen - was the result of strategic group decisions, whereby the processing of the wire rod produced in the steelworks was of primary importance.

1978

After giving up its wire rod interests, Krupp divested itself of WDI and transferred its shareholding to Klöckner-Werke AG, so that in 1978 WDI became a Klöckner Group company trading under the name Klöckner Draht GmbH. The development of the company on the fringes of the Klöckner steel group was not exactly favourable, and financial problems at Klöckner-Werke AG led to various considerations to liquidate the company, e.g. partial sale of large plant areas to LEG for the construction of a shopping centre, merger with Thyssen Draht or sale of the company to Voestalpine.

1987

Fortunately, these plans failed, so that an unusual arrangement came about, namely the sale of Klöckner Draht, 1/3 of the shares each, to Mr Grosse, Dr Weiland and Mr Pampus in 1987.Although there was a friendly business relationship with Hamburger Stahlwerke through Mr Grosse and Dr Weiland, the decisive factor was that when Werner Pampus joined as a partner and managing director, the company could be run as a non-group company according to the principles of a medium-sized enterprise, and once again under the old venerable name: Westfälische Drahtindustrie GmbH (WDI

Under the leadership of Werner Pampus, WDI becomes the largest independent wire manufacturer in Europe.

2009

Katja Pampus takes over the management.

The trained industrial clerk comes from a Westphalian family of entrepreneurs and is the second generation after her father Werner Pampus to successfully run Europe's largest, independent quality wire manufacturer. She has been a managing partner since 2009 and manages WDI with 15 locations and almost 1,300 employees.

She is committed to the preservation of European unity and is an active member of the VDU - Association of German Women Entrepreneurs. Since 2019, she has also been a member of the Board of the German Association of Small and Medium-Sized Enterprises (BVMW).